EAH Slurry Pump

Slurry Pumps.

eu-flo’s new Slurry pumps expand our line of dewatering pumping solutions to abrasive applications in the mining process and manure slurryindustries. With eu-flo’s patented Cermet® technology, our slurry pumps are built to operate without flush water.

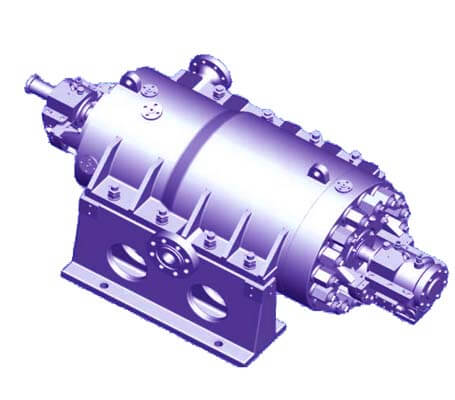

EAH/EHH-Series Pumps.

eu-flo’s EAH/EHH Series Slurry pump brings patented Cermet® technology to the mining process industry. Adding to the diverse range of mine dewatering pumps,The EAH/EHH Series Slurry pump offers a eu-flo solution to abrasive applications throughout the mill process. Available in rubber and metal lined configuration to handle various particle sizes, and pH requirements.

EAH/EHH-Series Pumps are designed to handle coarse abrasives while providing robust service life in a slurry pump.eu-fl0 Pump Company’s EAH/EHH Mining Pump Series combines 70 years of innovation in pump manufacturing and design, with our highly regarded patented Cermet® technology. Offering high operating pressures, the EAH/EHH pumpsare specifically designed for coarse abrasive slurry applications such as sand, gravel, coal, manure, and mine dewatering. The oversize shafts, thick volutes, CD4MCA impellers, and other features allow it to operate in harsh conditions longer than a standard slurry pump.

The EAH series incorporates the unique pushed-out rectangular design features of the Cornell frame, letting you know it is quality Cornell pump.

The EAH/EHH series are hard metal slurry pumps. All EAH/EHH pumps have a standard pressure rating of 600 PSI for high head and multistage series pumping applications. High chrome white iron alloy is the standard material of construction for all wet end components. A unique adjustable suction wear plate incorporates the newly patented Cycloguard feature to reduce recirculation for longer wear life.

Look for the distinctive appearance EAH/EHH Pump,with the angular, muscular frame, to know it’s a high quality Cornell pump.

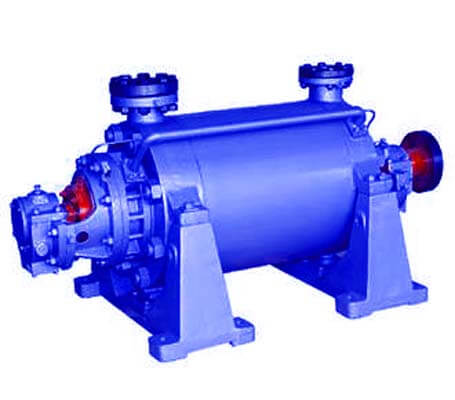

The products with the internationally advantage of technology from Warman, the centrifugal slurry pump are main Serial of EAH&EHH share many characters in common.

The Products EAH is a kind of horizontal centrifugal pump provided with cantilever. The shaft seal can be packing gland or mechanical seal. base on actual application, the pump discharge flange is adjustable, the angle for each adjustment is 45 degree.

The cantilever centrifugal slurry pump is application for delivery high corrosive slurry in high density in the industry of metallurgy, mine, coal ash, electric power, building material or others .

EHH centrifugal slurry pump, the impeller and the lining of the pump wet parts are made of wearing resistant metal or rubber, the lining for wear-resistant slurry pump is replaceable.

Features:

- Slurry pump propeller is dynamically balanced. Outer flanged columns are bolted together with through bolts for ease in assembly. Alignment is maintained via centering fits on all parts. Flared suction bell provides a smooth waterway entrance to the impeller and has intergral vanes to reduce inlet swirl and entrance losses. Seal chamber accepts packing or mechanical seal to suit service requirements. The pump also have anti-reverse rotation ratchet which will prevent high speed reverse operation due to backward direction of water flow

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in EU-Flo Pump.

- Revolutionary hydraulic performance design make the pump run at high efficiency.

- Special designed cleaning slot can release the solids and strips immediately.

- The special back angle of the impeller can thrust the solids or strips towards the out profile of the impeller and easy to be pumped out.

- High efficiency submersible squirrel cage save the power consumption.

- Optional cooling jacket allow the pump to be suitable for dry installation.

- Complete monitor system allow you to operate the pump without any concerns.

- The optional blade can cut the strips into chips effectively.

Benefits:

- Advance and modular design with fine production that is supplied by Eu-Flo Pump.

- High efficiency in long service time.

- Maintenance freely or less maintenance.

- Many choices for material, cast iron, hart steel, high chrome cast iron, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Ultra anti-clogging against solids and fabric strips.

- Long lifetime.

Application:

- Ball mill discharge

- Bottom/fly ash, lime grinding

- coal

- Coarse sand

- Coarse tailings

- FGD

- Fine Tailings

- Flotation

- Heavy media

- Minerals concentrate

- Mineral sands

- Ni Acid Slurry

- Oil Sands

- Phosphoric acid

- Phosphoric matrix

- Process chemical

- Pulp and paper

- Rod mill discharge

- SAG mill discharge

- Wet Crushers

Operation Range:

- Capacity

up to 1390L/s (5000m3h), or as per tailor-made.

- Head

up to 73m(240ft), or as per taitor- made.

- Working temperature

up to 120°C

- Design pressure

2.0Mpa

- Dis Flange

up to 500mm or tailor design. Flange standard can be DIN, AS,ANSI,JIS,GOST or other standard.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

EAH Slurry Pump

Slurry Pumps.

eu-flo’s new Slurry pumps expand our line of dewatering pumping solutions to abrasive applications in the mining process and manure slurryindustries. With eu-flo’s patented Cermet® technology, our slurry pumps are built to operate without flush water.

EAH/EHH-Series Pumps.

eu-flo’s EAH/EHH Series Slurry pump brings patented Cermet® technology to the mining process industry. Adding to the diverse range of mine dewatering pumps,The EAH/EHH Series Slurry pump offers a eu-flo solution to abrasive applications throughout the mill process. Available in rubber and metal lined configuration to handle various particle sizes, and pH requirements.

EAH/EHH-Series Pumps are designed to handle coarse abrasives while providing robust service life in a slurry pump.eu-fl0 Pump Company’s EAH/EHH Mining Pump Series combines 70 years of innovation in pump manufacturing and design, with our highly regarded patented Cermet® technology. Offering high operating pressures, the EAH/EHH pumpsare specifically designed for coarse abrasive slurry applications such as sand, gravel, coal, manure, and mine dewatering. The oversize shafts, thick volutes, CD4MCA impellers, and other features allow it to operate in harsh conditions longer than a standard slurry pump.

The EAH series incorporates the unique pushed-out rectangular design features of the Cornell frame, letting you know it is quality Cornell pump.

The EAH/EHH series are hard metal slurry pumps. All EAH/EHH pumps have a standard pressure rating of 600 PSI for high head and multistage series pumping applications. High chrome white iron alloy is the standard material of construction for all wet end components. A unique adjustable suction wear plate incorporates the newly patented Cycloguard feature to reduce recirculation for longer wear life.

Look for the distinctive appearance EAH/EHH Pump,with the angular, muscular frame, to know it’s a high quality Cornell pump.

The products with the internationally advantage of technology from Warman, the centrifugal slurry pump are main Serial of EAH&EHH share many characters in common.

The Products EAH is a kind of horizontal centrifugal pump provided with cantilever. The shaft seal can be packing gland or mechanical seal. base on actual application, the pump discharge flange is adjustable, the angle for each adjustment is 45 degree.

The cantilever centrifugal slurry pump is application for delivery high corrosive slurry in high density in the industry of metallurgy, mine, coal ash, electric power, building material or others .

EHH centrifugal slurry pump, the impeller and the lining of the pump wet parts are made of wearing resistant metal or rubber, the lining for wear-resistant slurry pump is replaceable.

Features:

- Slurry pump propeller is dynamically balanced. Outer flanged columns are bolted together with through bolts for ease in assembly. Alignment is maintained via centering fits on all parts. Flared suction bell provides a smooth waterway entrance to the impeller and has intergral vanes to reduce inlet swirl and entrance losses. Seal chamber accepts packing or mechanical seal to suit service requirements. The pump also have anti-reverse rotation ratchet which will prevent high speed reverse operation due to backward direction of water flow

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in EU-Flo Pump.

- Revolutionary hydraulic performance design make the pump run at high efficiency.

- Special designed cleaning slot can release the solids and strips immediately.

- The special back angle of the impeller can thrust the solids or strips towards the out profile of the impeller and easy to be pumped out.

- High efficiency submersible squirrel cage save the power consumption.

- Optional cooling jacket allow the pump to be suitable for dry installation.

- Complete monitor system allow you to operate the pump without any concerns.

- The optional blade can cut the strips into chips effectively.

Benefits:

- Advance and modular design with fine production that is supplied by Eu-Flo Pump.

- High efficiency in long service time.

- Maintenance freely or less maintenance.

- Many choices for material, cast iron, hart steel, high chrome cast iron, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Ultra anti-clogging against solids and fabric strips.

- Long lifetime.

Application:

- Ball mill discharge

- Bottom/fly ash, lime grinding

- coal

- Coarse sand

- Coarse tailings

- FGD

- Fine Tailings

- Flotation

- Heavy media

- Minerals concentrate

- Mineral sands

- Ni Acid Slurry

- Oil Sands

- Phosphoric acid

- Phosphoric matrix

- Process chemical

- Pulp and paper

- Rod mill discharge

- SAG mill discharge

- Wet Crushers

Operation Range:

- Capacity

up to 1390L/s (5000m3h), or as per tailor-made.

- Head

up to 73m(240ft), or as per taitor- made.

- Working temperature

up to 120°C

- Design pressure

2.0Mpa

- Dis Flange

up to 500mm or tailor design. Flange standard can be DIN, AS,ANSI,JIS,GOST or other standard.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.