Eu-Flo’s VTF series are single-stage (or multistage) single suction radial split case long shaft submerged pumps designed and fabricated as per API 610 11th Edition VS4 vertical Turbine Type. Pump shaft shall be supported by rolling bearings inside the bearing housing as well as sleeve bearings inside the column pipes. The pump shall be installed under water as deep as 6m. Selection chart is able to cover the range of the flow rate up to 400m3/h and head up to 80m. It is applicable for pumping clean or polluted media.

Structural support parts, bearing assembly and pump shaft follow the principle of standard design so as to facilitate better spare parts interchangeability and easy for manufacturing and maintenance. Rigid shaft is designed to guarantee stable operation of pump. The pump operating speed is designed well lower than the 1st critical speed of the rotor so as to guarantee the stable operation under severe conditions. Pump is of radial split casing structure; pumps with nominal flange nozzle lager than 80mm are designed as double volute structure to balance radial force and vibration caused by hydraulic actions.

VS4 type is vertical sump pump (sometimes called vertical Submerged pump) with centrifugal impeller, VS4 Vertical type Sump pump is completely according to application and performance request. which performance data can meet with ISO2858 and ISO 5199,The VS4 vertical sump pump is driven by standard motor IM V1. The underground column and shaft is divided into several sections, so VS4 type vertical sump pump is application for Lower NPSH and Wet pit installation and submerged pump. VS4 vertical type Sump pump can offer any tailor-made according to the project request.

Feature

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in EU-Flo Pump.

- Impeller options for closed , semi open and open type

- The shaft sealing is optional for mechanical seal and soft packing.

- The long column is flexible to get your desired length.

- The long shaft has several sections that is coupled together by sleeve clutches and fixed inside sleeve bearings to ensure the coaxial.

- Sand collar are used to stop the sand or solids.

- Shaft and lubricated bearing be protection by column for a long life time usage

- Upper stood is possible to tailor-made.

- Heavy duty service design for thrust bearing , the shaft can absorb the huge and unstable torque.

Benefits

- Advance and modular design with fine production that is supplied by EU-Flo Pump.

- impeller options for closed, semi open and open for vary liquid

- Flexible column length.

- Supper technical team and find production to ensure the tailor-made and best quality.

- Complete testing system to ensure the performance before delivery.

- Many choices for material, cast iron,cast steel, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Option External flushing from outlet of the pump can protection the sleeve bearing for a longer lift time usage.

- Epoxy coated parts submerged inside the liquid.

Application

- Molten sulphur

- Closed and open drains, drums and sumps

- Process condensate

- Amine mixing

- Stabiliser reboiler

- Oily water seperation

- Hydrolyzer feed

- Vapour recovery

- Condensed water injection

- Foul and sour water service

- Metal Smelting

- Hydrofiner/hydrotreater drains

- Acid gas K.O. drums

Operation Range

up to 111L/s (400m3h), or as per tailor-made.

up to 80m(262.5ft), or as per taitor- made.

up to 100°C

1.6Mpa / 2.5Mpa

up to 350mm or tailor design. Flange standard can be DIN, AS,ANSI ,JIS,GOST or other standard.

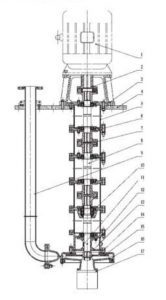

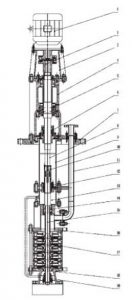

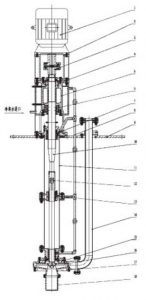

VS4 PUMP CROSS SECTION DRAWING (I)

| No | Parts Description |

| 1 | Motor |

| 2 | Coupling |

| 3 | Mount-Motor |

| 4 | Base-Plate |

| 5 | Column(Uper,Mid,Lower) |

| 6 | Bearing Housing(Mid) |

| 7 | Coupling(Mid) |

| 8 | Shaft |

| 9 | Discharge Pipe |

| 10 | Bearing |

| 11 | Mechanical Seal |

| 12 | Sealing Chamber |

| 13 | Sealing Cap |

| 14 | Casing(Upper) |

| 15 | Impeller |

| 16 | Casing(Lower) |

| 17 | Strainer |

Advantage of the Section (I)

1.Patented structure. The middle brake shaft is supported by double bearings. The middle brake coupling adopts an elastic coupling. No axial force is transmitted between the shaft and the shaft. Only the torque is transmitted, which Improves the operation stability of the pump unit

2.The middle bearing adopts metal rolling bearings. No external coolant system is required. It has the advantages of long service life, stable operation, low vibration and low noise.

3.Adopting the idea of modular structure design. The pump is composed of different parts, and the parts are highly interchangeable. Easy to transport

4.The shaft seal adopts the sealing type of sand-proof disk, auxiliary impeller and double-end mechanical seal, which effectively isolates the medium from the rotor parts and prolongs the service life of the equipment. No need to supply cooling water outside, saving operating costs

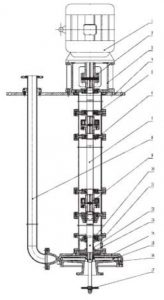

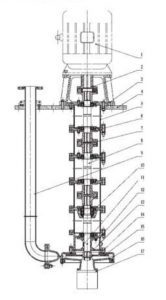

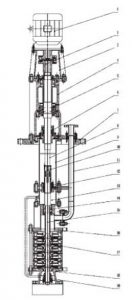

VS4 PUMP CROSS SECTION DRAWING (II)

| No | Parts Description |

| 1 | Motor |

| 2 | Coupling |

| 3 | Mount(Motor) |

| 4 | Base Plate |

| 5 | Column(Uper,Mid,Lower) |

| 6 | Bearing Housing(Mid) |

| 7 | Shaft |

| 8 | Discharge Pipe |

| 9 | Coupling(Mid) |

| 10 | Bearing |

| 11 | Sealing Chamber |

| 12 | Mechanical Seal |

| 13 | Sealing Cap |

| 14 | Casing(Upper) |

| 15 | Impeller |

| 16 | Casing(Lower) |

| 17 | Cutter |

Advantage of the Section(II)

Advantage of the Section(II)

1.Patented structure. The middle brake shaft is supported by double bearings. The middle brake coupling adopts an elastic coupling. No axial force is transmitted between the shaft and the shaft. Only the torque is transmitted, which Improving the operation stability of the pump unit

2.The middle bearing adopts metal rolling bearings. No external coolant system is required. It has the advantages of long service life, stable operation, low vibration and low noise.

3.Adopting the idea of modular structure design. The pump is composed of different parts, and the parts are highly interchangeable. Easy to transport

4.The shaft seal adopts the sealing type of sand-proof disk, auxiliary impeller and double-end mechanical seal, which effectively isolates the medium from the rotor parts and prolongs the service life of the equipment. No need to supply cooling water outside, saving operating costs

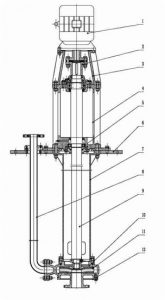

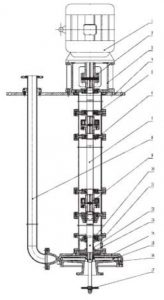

VS4 PUMP CROSS SECTION DRAWING (III)

| No | Parts Description |

| 1 | Motor |

| 2 | Coupling |

| 3 | Mount(Motor) |

| 4 | Bearing Support |

| 5 | Bearing |

| 6 | Base Plate |

| 7 | Column |

| 8 | Discharge Pipe |

| 9 | Shaft |

| 10 | Casing(Upper) |

| 11 | Impeller |

| 12 | Casing(Lower) |

Advantage of the Section(III)

Advantage of the Section(III)

1.This type of pump is improved on the basis of the type I pump. The lower main shaft of the pump extends out of the inlet of the pump. A stirring device is added near the inlet of the pump. It works synchronously with the impeller. It is suitable for conveying sewage (such as pulverized coal. Fly ash water)

2.The stirring wheel is equivalent to adding a stirrer at the inlet of the pump. It is conducive to the pump to fully discharge impurities and sewage.

3.It effectively prevents the accumulation of sediment from blocking the pump inlet and causing damage to the impeller, pump or motor.

4.Due to the sufficient discharge of impurities, the cleaning cycle of the pool is extended, saving the user’s operation and maintenance costs

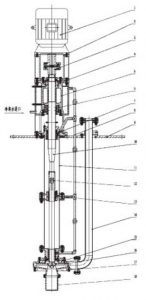

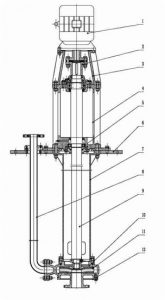

VS4 PUMP CROSS SECTION DRAWING (IV)

| No | Parts Description |

| 1 | Motor |

| 2 | Mount(Motor) |

| 3 | Coupling |

| 4 | Bearing |

| 5 | Bearing Support |

| 6 | Bearing |

| 7 | Mechanical Seal |

| 8 | Cooling Pipe |

| 9 | Base Plate |

| 10 | Shaft |

| 11 | Column(Uper,Mid,Lower) |

| 12 | Coupling(Mid) |

| 13 | Ball Bearing |

| 14 | Discharge Pipe |

| 15 | Casing(Upper) |

| 16 | Impeller |

| 17 | Casing(Lower) |

| 18 | Strainer |

Advantage of the Section (IV)

1.The fixed point of the bearing is moved up, using a single rigid shaft structure, and there is no bearing support at the lower end of the shaft. It is used for high temperature, high concentration slurry, easy crystallization and other special media transportation.

2.The impeller adopts a wide flow channel design and CFD flow field calculation. It has excellent two-way conveying capacity, impurity passing capacity, and superior wear resistance. Shaft-free system, simple structure, stable and reliable operation, long life, with different cooling methods, the highest conveying medium temperature can reach 260°C

3.The method of adding a suction pipe can be used in a deeper pool, effectively preventing the sedimentation medium from blocking the impeller and causing equipment damage.

VS4 PUMP CROSS SECTION DRAWING (V)

| No | Parts Description |

| 1 | Motor |

| 2 | Coupling |

| 3 | Mount(Motor) |

| 4 | Bearing Support |

| 5 | Bearing |

| 6 | Mechanical Seal |

| 7 | Base Plate |

| 8 | Shaft(Uper) |

| 9 | Column |

| 10 | Coupling(Mid) |

| 11 | Discharge Pipe |

| 12 | Ball Bearing |

| 13 | Balance Chamber |

| 14 | Balance Drum |

| 15 | Shaft(Lower) |

| 16 | Discharge Pipe |

| 17 | Impeller |

| 18 | Suction Pipe |

| 19 | Shaft Sleeve |

Advantage of the Section (V)

Advantage of the Section (V)

1.Taking advantage of No IV pump, this type of pump adopts a multi-stage impeller structure, which has a wider range of parameters. Equipped with a dedicated cooling system, the maximum conveying medium temperature is as high as 260℃

2.The multi-stage impeller structure has a smaller radial size, which can meet the installation requirements of a smaller pool.

3.The specially designed axial force balance mechanism can effectively balance the axial force, and the equipment operation is more stable and reliable.