The Submersible pump technical characteristics been analyzed by The pump manufacture in china

The Submersible pump technical characteristics been analyzed by The pump manufacture in china

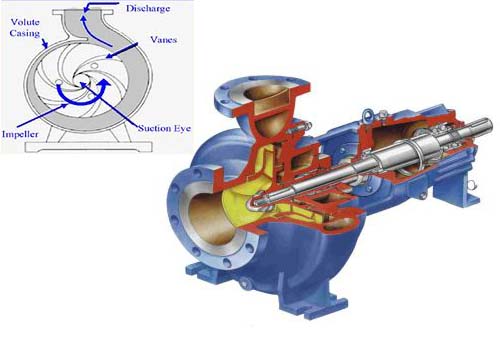

Similar to a conventional water pump, a submersible pump can be used for drainage in most applications, the only condition being the needed is a stable power supply to drive the motor.

Submersible Pumps Main features:

1) The submersible pump is directly coupling to the motor. The small submersible pump even fixed the pump impeller directly on the motor shaft, eliminating many connected parts, shortening the overall size of the pump, reducing material consumption and reducing weight. When the submersible pump been instead of the deep well pump application, and reducing the deep well pump’s problem of long-shaft failure rate , and improving the equipment reliability.

2) The characteristics of the submersible pump are simple to installation, no need to build a pump Room, small civil construction area, reduced infrastructure investment, and the submersible pump directly diving into the water, only need the ground construction of electrical control equipment, easy to use and maintain.

3) The characteristics of the submersible pump are also low noise operation under water. It is suitable for water supply and drainage in places where the working environment requires quiet, such as schools, hospitals, hotels, and halls.

4) The submersible pump is operated underwater. The characteristics of the submersible pump are not affected by the climate and the surrounding working environment; it is easy to conceal and is suitable for combat preparation and strategic needs.

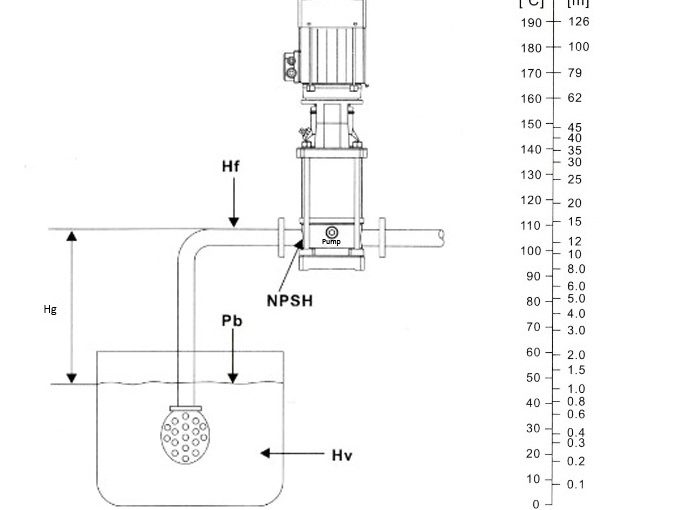

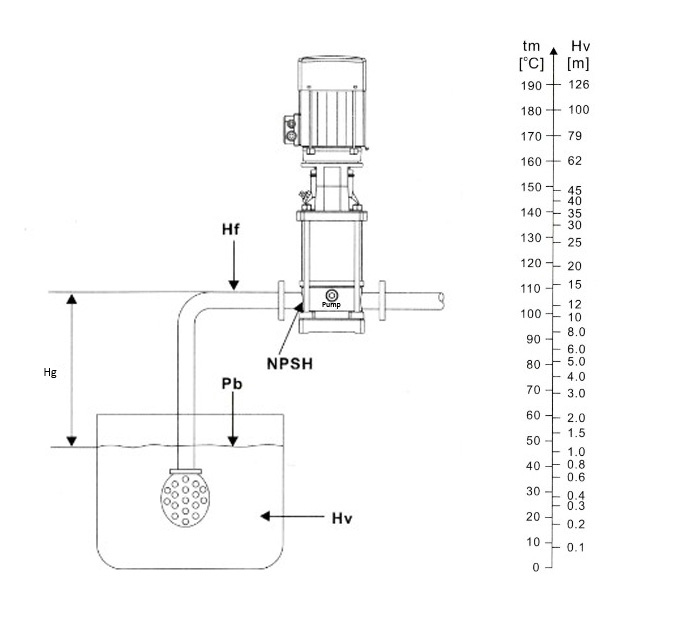

5) Using the submersible pump to lift water, the depth of water lifting increases, and the problem of cavitation is less.

6) The Interior submersible motor can ensure that the Electric submersible pump can operate for a long time even when it is approaching to the draining sink, and there is no need to worry about the problem that the motor has a high temperature and burns due to a large unload current.

7) Technical characteristics of submersible pumps may cause leakage, water in cable, mechanical seal leakage and other static sealing components. These problems may cause the whole pump to burn or cause electric leakage.

pump manufacturers in china|eu-flo pump

pump supplier in china|eu-flo pump