BLOG

Select a corrected Mechanical Seal for a Centrifugal Pump

May 20,2021

Every centrifugal pump needs some way to prevent the product liquid from leaking past the spinning drive shaft. The method of sealing can be as simple as packing rope impregnated with graphite into a “packing box” and as complex as enclosing the whole pump in a chamber (mag drive or canned motors). By far the most common way of sealing around the pump shaft is using a mechanical seal.

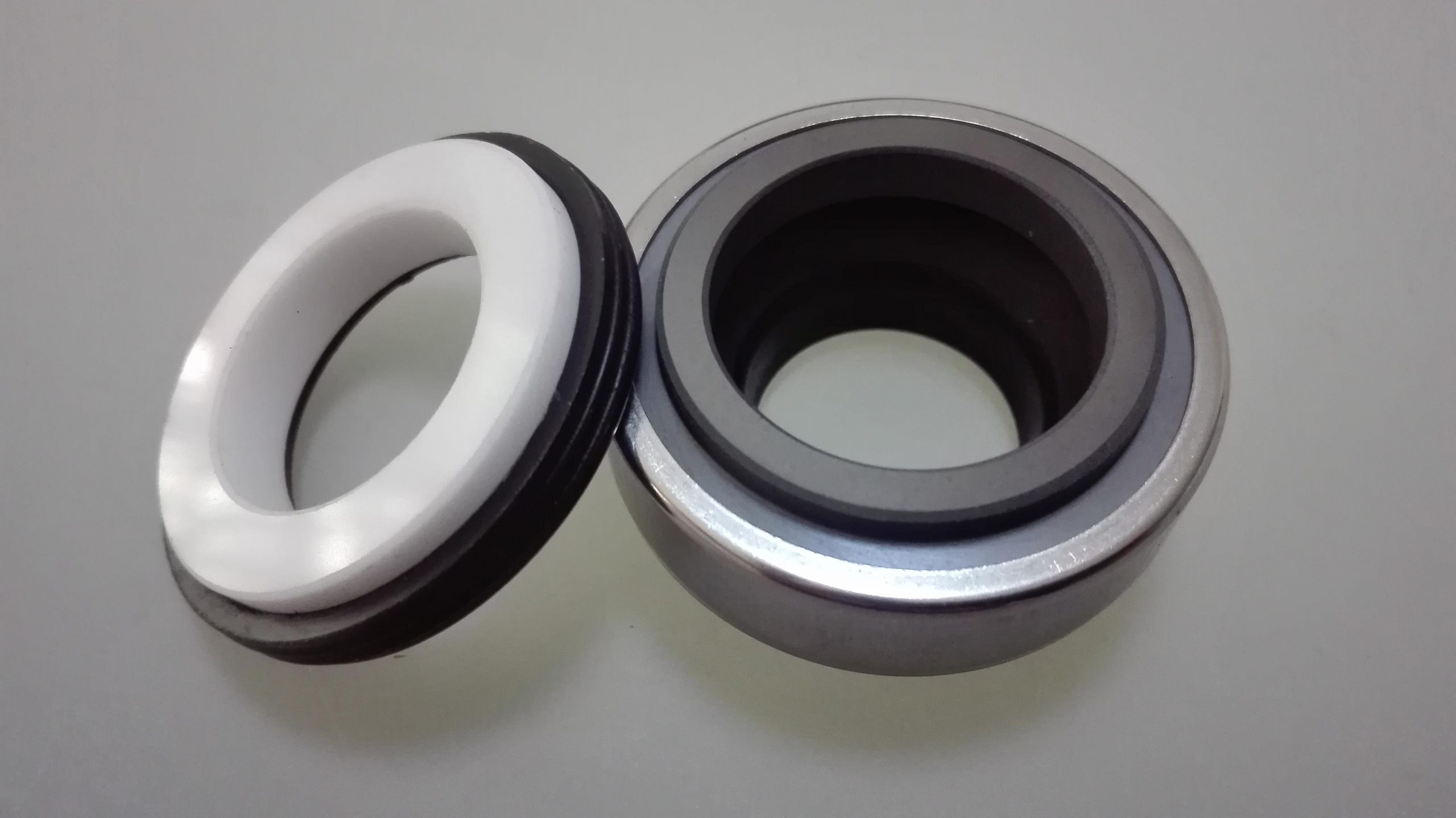

Mechanical Seal A mechanical seal is any device that utilizes two ring type seal faces running against each other to create a barrier to the leaking product liquid. These two seal faces are ground and polished so smooth that they can run with a very small clearance between them, and even occasionally touch momentarily without damaging one another. The mechanical seal uses the product liquid to cool and lubricate the seal faces to keep them undamaged, with small amounts of vapor escaping across the faces. For liquids that are abrasive and non-lubricating, a “barrier fluid” may be required to protect the seal faces from the product.

The simplest mechanical seal consists of one “stationary face” that attaches to the exterior of the pump and does not rotate, and one “rotating face” that attaches to the spinning shaft. Each of these faces must attach to the pump via flexible “boots”, O-rings or other means to prevent liquid from leaking out around the seal faces. These boots are typically made of an elastomer such as rubber (BUNA), EPR or Viton, but the boots can be flexible metal bellows or even Teflon (although Teflon is difficult to install and keep compressed).

Metal parts are needed to keep the parts together and to provide springs to keep the faces together. These metal parts are usually 316SS but can be made from other more noble metals if needed.

A vast majority of centrifugal pumps will pump water in some varied condition, possibly in combination with an antifreeze and some antibacterial additives. Since water by itself is not a very good lubricant (especially at high temperatures) the seal faces need to provide some lubricity of their own so that when they touch at startup or shutdown, the faces will not tear themselves up. This is usually accomplished by making one of the seal faces out of carbon or by some material impregnated with carbon. The other seal face is usually a harder material that will resist wear from the carbon face, such as a ceramic, carbide or solid metal.

Note that although water is the most common liquid pumped, the different additives used can make a huge difference in the type of seal required. Relatively clean water, even when combined with glycol, is easy and inexpensive to seal, whereas dirty water or water with lots of additives can be very difficult. The difference is in the abrasiveness and lubricity of the liquid. If when you rub a sample between your fingers you can feel the lack of lubricity, or if your liquid has lots of salts or other dissolved solids, you may need a more complicated and expensive mechanical seal.

Clean Water Mechanical Seal

Water that is not abrasive and may have some glycol can use the least expensive type of seal. The stationary seal face is usually made of ceramic and is sealed to the seal plate with a Buna boot or a Buna O-ring. The rotating seal face is usually made of carbon/graphite in some combination and is sealed to the shaft (or shaft sleeve) with a Buna boot or O-ring. The spring and metal parts needed to hold the seal together are 304SS or 316SS.

Water with Salts, Abrasives or Additives

Water with any salts, abrasives or additives are much harder on mechanical seal faces. When the mechanical seal is operating properly, small amounts of liquid are entering the space between the two faces. As the liquid travels from the high pressure side of the faces to the low pressure side, the liquid heats up and vaporizes. While this vaporization is needed to cool and lubricate the faces, it also leaves any salts or other solids in the space between the seal faces. These deposited solids are very abrasive and will accumulate over time and may quickly erode the faces (particularly the softer carbon face).

The simplest and cheapest solution for mildly abrasive liquids is to upgrade the seal faces to materials that can resist abrasives better than the inexpensive carbon/ceramic combination used for clean liquids. The least expensive harder material is usually silicon carbide, but other ceramic/metals are used. The downside of silicon carbide or any other hard material occurs when they run dry, even momentarily during startup and shutdown. Any period of dry running can cause wear and heat buildup and may cause the mechanical seal to fail. (In severe cases, the heat will melt the elastomeric parts). This dry running problem is significantly reduced when the silicon carbide faces are impregnated with carbon/graphite, but the problem is not eliminated. Depending on many variables, the seal with impregnated faces can only run dry for a short time before failing, but eventually the seal will fail from heat buildup.

Other solutions for sealing abrasive liquids include flushing the seal faces with a clean liquid, but this option requires special seals (such as a double seal) and special flushing piping. The cost of this option gets expensive fast and may require a much larger, more expensive pump and seal combination.

Water at High or Low Temperatures

As water temperature gets lower than 32 F or higher than 212 F, the seal materials may need to be upgraded. Low temperatures usually need EPR elastomers to handle the cold, and higher temperatures may need Viton. Extreme temperatures may also require that the standard ceramic be replaced with the much tougher silicon carbide or other metal faces. Ceramic faces are very susceptible to thermal shock, and a sudden change in the temperature of the liquid can shatter the seal faces.

Food Grade Seals

Mechanical seals for sanitary pumps or for use in food processing will usually require Viton elastomers and 316SS metal parts plus any other material upgrades needed for the liquid being pumped. These seals usually must be outside the pump where they can be disassembled and cleaned daily, so specialized pumps and seals are needed.

Liquids other than Water

Liquids other than water may require very specialized mechanical seals, and even very specialized pumps. Toxic or flammable liquids will require double seals, special flushing liquids and special flushing plans to isolate the liquids and protect the seal faces. These special seals are often required for protecting workers, the public and the air quality. The size and complexity of these special seals requires large chambers and often large, complicated and expensive pumps. You may need to consult with your pump salesman or an experienced mechanical seal salesman to get the right pump and the right mechanical seal.

Pumps that do not need a Mechanical Seal

If your liquid is very hard to seal or very dangerous, you may want to consider a “sealless” pump. The three most common types of sealless pumps are: Mag Drive Pumps, Canned Rotor Pumps and Vertical Cantilever Pumps.

A Mag Drive Pump uses magnets to drive the pump in a contained shell. One set of Magnets spins on an outside cylinder attached to the motor. Another set of magnets spins on an inside cylinder attached to the pump. The two sets of magnets are separated by a thin non-metallic shell that keeps the pump liquid inside the shell. The problem with this arrangement is that there are lots of bushings and sleeves needed to support the pump shaft and the impeller. These bushings and sleeves are exposed to the pumped liquid, so any abrasives can kill the pump quickly. Repairing or replacing these bushings and sleeves is very difficult and very expensive, and only adds to the cost of an already expensive pump. This pump is very useful for clean but dangerous liquids.

A Canned Rotor Pumps goes one step farther than a Mag Drive Pump by enclosing the whole pump and motor inside a sealed shell. This eliminates the need for magnets to drive the pump and uses fewer bearings/bushings than the Mag Drive Pump. These bushings and sleeves are exposed to the pumped liquid, so any abrasives can kill the pump quickly. The repair and replacement of the bushings and sleeves is very expensive. This pump can be the best option for some hot and dangerous liquids.

A Vertical Cantilever Pump is usually the best option for water with lots of abrasives (such as parts washers). A motor is specially designed and built to have a very long and often very large diameter shaft that extends out (cantilevered) as long as is needed for the pump design. This long motor shaft is supported solely by the motor ball bearings (or by a large bearing housing) and these bearings are not exposed to the pumped liquid. A throttle bushing and sleeve are needed to reduce the amount of water escaping from the pump and these parts are exposed to the liquid, but the bushing and the sleeve should never touch and can be made from hard, erosion resistant materials. The disadvantage of this pump is that it is mounted vertically and must hang into a sump, so a lot of space and additional support structure is required. There are limits to the length these pumps can be made as the diameter of the shaft goes up exponentially as the length of the shaft increases. There is also some lost efficiency as some liquid must leak past the sleeve and bushing.

- More

The Analysis of Various Sump Pumps

May 9,2021

The Analysis of the Technical Requirements for Various Sump Pumps

The mechanical seal is a kind of high quality component, which requires high quality of planning, machining and installation. The mechanical seal of the sump pump is also called end face seal. It has a pair of end faces perpendicular to the axis of rotation, with the effect of the fluid pressure and the external elasticity of the sump pump, the pump depends on the support of the auxiliary seal and the other end to adhere to it, and slide relative to the other end to avoid fluid leakage.

In the mechanical seal of sump pump, there are different reasonable requirements of planning, selection and installation. In the process of mechanical seal, we should analyze the various factors of mechanical seal of pump. The mechanical seal of the sump pump is suitable for the requirement of the pump and the requirement of the medium and the smooth condition, so that the pump seal can be guaranteed to work reliably for a long time.

(1)The installation of the shaft end of the ring of the moving ring of the pump and the end face of the sealing gland (or shell) of the seal ring should be Chamfered and trimmed, so as to avoid the damage to the sealing ring of the dynamic ring.

(2) the retrenchment of the pump spring must be carried out according to the rules, which shall not be allowed to be too large or too small, and the error shall be plus or minus 2 mm. If large amount of austerity, then add the face specific pressure, if conflict too much heat, it can form liquid pump sealing surface thermal deformation and speed up the face under wear, if quantity is too small, so the dynamic ring end face specific pressure is insufficient, it can not be sealed.

In the process of mechanical seal, we should analyze the various factors of mechanical seal of pump. The mechanical seal of the sump pump is suitable for the requirement of the pump and the requirement of the medium and the smooth condition, so that the pump seal can be guaranteed to work reliably for a long time. The mechanical seal itself is a kind of high quality component, which requires high quality of planning, machining and installation.

- More

flushing Methods for Sump Pump

May 9,2021

Flushing Methods for Sump Pump

Remove grit from pumpedfluids to safely flushbearings and seals.Pumpshandling dirty fluids risk damage to the mechanical seal and line shaft wet bearings if they are not continuously flushedby clean fluids. When clean water is available, it can be routed through small diameter tubing forlubricating and cooling purposes. However, clean water is often unavailable, too costly and sometimes the addition of water cannot be tolerated. In these cases, a cyclone separator can be employed to remove dirt and grit from the fluid being pumped,before safely using it forthe seals and bearings.

The sump pump chooses the common impeller structure and new mechanical seal to transport solid and long fibers efficiently. Compared with the traditional impeller, the impeller uses single runner or double channel method. It is similar to a section of a large section of the bend tube, with very good overflows, with reasonable cochlear chamber, the pump has high efficiency and dynamic balance experiment of impeller, so that the pump has no vibration at work and low noise.

The equipment and maintenance of the pump are difficult, and the equipment is in a mess. Therefore, the application of the pump in the fluid should be based on the condition request, and the reasonable application and maintenance cycle should be worked out. The repair and maintain the breakdown before failure, and reduce the abnormal failure rate and facilitate the disassembly, and reduce unnecessary parts damage and reduce work costs.

In the process of application of the pump, the appropriate sealing method is selected according to the actual conditions: packing seal or mechanical seal. The pump in the long axial fluid pumps the liquid directly out of the individual outlet pipe, and the axial direction of the pump does not have a liquid leak. Therefore, the shaft seal is not required normally. However, if the liquid is toxic, volatile and not allowed to leak into the atmosphere in a closed container, the shaft seal is required.

According to the different pump medium, the scour method should be selected rationally. In the working process of YW liquid sewage pump, it is necessary to flush the bearing and sleeve to reach the cooling and smooth effect. The accurate selection of scour method affects the safety of pump. There are two kinds of flushing methods for YW submerged sewage pump: self washing and external flushing:

1. Self-flushing method: the flushing method can be used when the pump medium is the cleaning medium. In the pump outlet flanges, a pipe is brought out to flow the flushing liquid to each sliding bearing, smooth bearing and take away the heat of the conflict, and the bearing temperature.

2. External flushing method: when the pump medium is included in the smaller particle medium, it needs to take a line from the outside, the cleaning fluid is introduced to flush the bearings and remove the heat from the side of the conflict, while avoiding the solid particles entering the conflict. In the sewage treatment system, the external flushing method is more common.

- More

The Maintenance of the Failures of the Clean Water Pumps

March 21,2021

The Maintenance of the Failures of the Clean Water Pumps

The water clean pump is the integral of motor and water pump, and the bearing of the motor rotor is a pump bearing. The pump impeller rotating work reducing valve is presented with rigid power transmission. There is a gap between 0.10-0.22 mm of water pump impeller and the vortex shell debris, sand stuck dead impeller, the litter granule is easy to get the impeller stuck, and make the motor rotor unable to rotate and malfunction. The failure analysis of the water clean pump accounted for more than 80% of the damage caused by the stuck of the impeller. When the power switch is turned off, if the motor is not turned, the power should be turned off in time. The motor will be used to generate the rotating magnetic field in the working time, and the motor will not be damaged in a short time. You can use a screwdriver to remove the back cover of the motor, and turn the fan blade to the back of the back cover.The repair of impeller and swig ring

After a certain period of time, the pump should be repaired and disintegrated after a period of 6 months. The impeller and the swig ring are vulnerable parts, and should be repaired and replaced regularly. The main damage form of impeller and swig ring is wear, resulting in the change of clearance. When the clearance exceeds a certain value, the efficiency of water clean pump drops sharply, accompanied by a large vibration and noise, which must be repaired at this time. The time interval between this kind of damage is generally proportional to the running time of the pump, and it can be used for preventive maintenance. Generally speaking, the pump with the impeller is located in the middle part is easiest to wear (head impeller material is alloy cast steel, the other impeller for the production of cast iron), and the big ring wear heavier, impeller inlet diameter wear lighter, at this point, the impeller can be used to cut the entrance to the lathe slightly, or sand cloth to polish smooth, then, according to the outer diameter of the impeller inlet, the new opening ring should be changed to meet the original matching requirements. In order to improve the efficiency of maintenance, we can mark the opening and impeller during the repair process to avoid confusion and increase maintenance.

When the outer diameter of the impeller inlet is larger, it can be repaired by surfacing, plating and spray-welding repair. In the case of surfacing welding, it shall be used for surfacing welding of the same quality welding rod. After surfacing welding, it is necessary to pay attention to the insulation of the welding zone to prevent the appearance of the white mouth tissue. Then the grinding of lathe or grinding machine is to reach the specified size. When the outer diameter of the impeller entrance is badly worn or broken, the repair value has been lost and the new one can be replaced.

During the maintenance, attention should be paid to the internal clogging of the impeller. Because there will be many impurities in the mine water, such as small pieces of wood, bark, small coal, etc. They are often stuck in the passage of the impeller, affecting the flow and efficiency of the pump, which occurs more in the first and second stage impeller and must be removed. Several gaps that need to be guaranteed during the repair process: the gap between the size and mouth is 0.4 ~ 0.5 mm, the interplay clearance between the outer and guide vane inlet of the water wheel is 0.8 ~ 1.2 mm, the inner and outer space of the countervail of the balance plate is 0.8 ~ 1.0 mm.

The common methods for straightening of pump shaft bending

(1) the shaft is placed on the platform with the manual screw corrector. It is supported by two v-shaped iron, and then the curved part of the convex surface is facing up, so that the screw is held up.

Then rotate the handle to tighten the screw head on the pump shaft. The corrector can move in the direction of the axial bend and repeat the correction several times until it is completely straightened (and has a certain amount of reverse bending).(2) the method is to use a twister to direct the alignment of the axis by bending the curved surface of the axis, and the surface of the shaft is extended and straightened. When straightened, the concave of the shaft is facing up, and the maximum bending of the convex surface as a support point, tightly supported, and the ends are pressed by the card, then, with a 1~2 kg hammer, knock the twig, and the surface of the concave surface of the shaft is hit and extended. Start by tapping into the center of the lowest concave, and gradually moves to the sides, and it goes on the arc of a third of the circumference, but the more it goes to the center, the greater the density. Be careful not to damage the surface of the shaft.

(3) the shaft of the heating straightening pump is at the convex surface of the larger bend, and heat it locally, and control the temperature under 600 ℃, then, the two ends of the axis can be found, and the underside cushion should be placed below. Add pressure to the biggest bend (convex surface). The temperature should rise slowly and not too fast. Heating area and pressure size should be determined according to specific conditions. The supporting plate is lower than the requirement of the straightening position, generally 1~ 4 mm, which is related to the type of shaft material, heating temperature, pressure size and speed of casting. After the pump shaft alignment meets the requirements, the asbestos insulation number for the axial heating area is cooled by h. After straightening, the shaft should be annealed to make the shaft rotate slowly. When heated to a temperature of about 350 ℃, heat preservation more than 1 hour, and then wrapped it in the heat, when cooled to about 70 ℃ with the rotation of the axis, and then natural cooling in the air.

- More

Energy Saving Methods of Pumps

March 21,2021

Energy Saving Methods of Petrochemical Industrial Pumps

Improve the pump efficiency , it is work hard in the design and manufacture of the pump, we can use advanced design and processing methods to make the pump, or adopt advanced technology to realize the efficiency of the pump utilization.According to the introduction, there are more than 100 manufacturers of petrochemical pumps in China. In addition to the general pump, chemical processing pump and water pump, independent research and development or the introduction of foreign technology in recent years, and developed a high temperature and high pressure feed pump, oil refining and petrochemical plants high-speed pump, cryogenic pump, shielding pump and chemical process pumps, parts meet the demand of the petrochemical production. The product quality has been improved greatly, the specification has been further increased to meet the needs of 80% of petrochemical industry in the domestic petrochemical industry.

However, compared with the advanced level of foreign countries, there is still a gap in the design theory and design method of petrochemical pumps in China. In particular, the development of hydraulic components in the early stage is not sufficient, in the research and development of hydraulic components of the pump, the production, learning, research is seriously decoupling. In general, the production technology of foreign petrochemical pumps is mature, the specifications are much, the standardization degree is high. The development direction of foreign countries is large-scale, quick running, electromechanical integration and pump products, standardization, seriation and generalization, many varieties, wide performance, long service life and high reliability, high efficiency, miniaturization, pump seal, bearing production of large-scale and specialization. In particular, high temperature, low temperature and ultra-low temperature pumps, high-speed pumps, precision metering pumps, anti-corrosive pumps, transporting viscous media and solid particle media pumps, shielding pumps and other products have developed rapidly.

1. The application frequency converter changed the speed of the pump and improved the operation efficiency of the pump.

The practice proves that the variable frequency speed regulating device is an ideal equipment for enterprise technological transformation and energy saving and consumption reduction. There is no doubt that this kind of speed regulating mode will be the center of the driving system in the petrochemical enterprise, the choice of pump class, and the selection of the type according to the load work. In practice, the pump is not operating at full capacity for most of the time.

It is a scientific method to control pump load directly by inverter.

Because the frequency converter can realize the soft stop and soft start of big motor, and avoid the voltage shock at startup, and it can reduce the failure rate of the motor, and prolong the use of orders. It also reduces the capacity requirement and reactive power loss of the power grid. Therefore, the promotion of the use of inverter for the purpose of energy conservation has become the focus of energy saving work departments and energy conservation work of various units.2. The selection of pump and the correct use of the pump also determine the real realization of the energy saving and consumption of the petrochemical industry

The manufacturing enterprises have the responsibility to communicate with customers, and provide reasonable product models and related services, and the user must have a good selection of this to prevent the phenomenon of unnecessary energy consumption of “big house drives small car”.

The pump is the heart of the refinery, and the total amount of logistics during the refining process is about 40 times that of crude oil processing, so it is conceivable that the power consumption is large. In the refining plant, the electric motor is one of the most widely used electrical equipment. And most of its load is machine pump, and the fixed speed pump is only 30% ~ 40% of the power consumed by process logistics. And 60% ~ 70% of the power consumption is due to the pressure drop of the throttle control and the pressure drop of the pump outlet valve caused by the capacity of the handling capacity and the design margin.

Therefore, as the manager and the user of the pump, the pump should be selected rationally, and the selection should be reasonable. The matching of each component (pump, motor, various accessories) is the best and most reasonable. It is the key to improve the operation efficiency of pump. Secondly, it is necessary to select the appropriate modulated mode. Here are two conditions: the pump needs to be adjusted in time for the process flow or the pump itself is set to adjust the process parameters.

In the regulation, we should try to choose the variable speed regulation, do not need throttling regulation. As for the way to speed regulation, we should also analyze specific problems. If process parameters are basically stable, pump selection is too large, we take down the valve at the scene to regulate traffic, which can cause the pump work flow is far less than the rated flow, working pressure is much higher than the rated pressure, then, we can adopt the way of comparatively economy of cutting impeller outer diameter to adjust.

- More

Washing Methods for Sump Pump

March 18,2021

Washing Methods for Sump Pump

The sump pump chooses the common impeller structure and new mechanical seal to transport solid and long fibers efficiently. Compared with the traditional impeller, the impeller uses single runner or double channel method. It is similar to a section of a large section of the bend tube, with very good overflows, with reasonable cochlear chamber, the pump has high efficiency and dynamic balance experiment of impeller, so that the pump has no vibration at work and low noise.The equipment and maintenance of the pump are difficult, and the equipment is in a mess. Therefore, the application of the pump in the fluid should be based on the condition request, and the reasonable application and maintenance cycle should be worked out. The repair and maintain the breakdown before failure, and reduce the abnormal failure rate and facilitate the disassembly, and reduce unnecessary parts damage and reduce work costs.

In the process of application of the pump, the appropriate sealing method is selected according to the actual conditions: packing seal or mechanical seal. The pump in the long axial fluid pumps the liquid directly out of the individual outlet pipe, and the axial direction of the pump does not have a liquid leak. Therefore, the shaft seal is not required normally. However, if the liquid is toxic, volatile and not allowed to leak into the atmosphere in a closed container, the shaft seal is required.

According to the different pump medium, the scour method should be selected rationally. In the working process of YW liquid sewage pump, it is necessary to flush the bearing and sleeve to reach the cooling and smooth effect. The accurate selection of scour method affects the safety of pump. There are two kinds of flushing methods for YW submerged sewage pump: self washing and external flushing:

1. Self-flushing method: the flushing method can be used when the pump medium is the cleaning medium. In the pump outlet flanges, a pipe is brought out to flow the flushing liquid to each sliding bearing, smooth bearing and take away the heat of the conflict, and the bearing temperature.

2. External flushing method: when the pump medium is included in the smaller particle medium, it needs to take a line from the outside, the cleaning fluid is introduced to flush the bearings and remove the heat from the side of the conflict, while avoiding the solid particles entering the conflict. In the sewage treatment system, the external flushing method is more common.

- More

The Maintenance of the Failures of the Water Clean Pumps

February 23,2021

The Maintenance of the Failures of the Water Clean Pumps

Energy Saving Methods of Petrochemical Industrial Pumps Improve the pump efficiency , it is work hard in the design and manufacture of the pump, we can use advanced design and processing methods to make the pump, or adopt advanced technology to realize the efficiency of the pump utilization.

According to the introduction, there are more than 100 manufacturers of petrochemical pumps in China. In addition to the general pump, chemical processing pump and water pump, independent research and development or the introduction of foreign technology in recent years, and developed a high temperature and high pressure feed pump, oil refining and petrochemical plants high-speed pump, cryogenic pump, shielding pump and chemical process pumps, parts meet the demand of the petrochemical production. The product quality has been improved greatly, the specification has been further increased to meet the needs of 80% of petrochemical industry in the domestic petrochemical industry.

However, compared with the advanced level of foreign countries, there is still a gap in the design theory and design method of petrochemical pumps in China. In particular, the development of hydraulic components in the early stage is not sufficient, in the research and development of hydraulic components of the pump, the production, learning, research is seriously decoupling. In general, the production technology of foreign petrochemical pumps is mature, the specifications are much, the standardization degree is high. The development direction of foreign countries is large-scale, quick running, electromechanical integration and pump products, standardization, seriation and generalization, many varieties, wide performance, long service life and high reliability, high efficiency, miniaturization, pump seal, bearing production of large-scale and specialization. In particular, high temperature, low temperature and ultra-low temperature pumps, high-speed pumps, precision metering pumps, anti-corrosive pumps, transporting viscous media and solid particle media pumps, shielding pumps and other products have developed rapidly.

1. The application frequency converter changed the speed of the pump and improved the operation efficiency of the pump.

The practice proves that the variable frequency speed regulating device is an ideal equipment for enterprise technological transformation and energy saving and consumption reduction. There is no doubt that this kind of speed regulating mode will be the center of the driving system in the petrochemical enterprise, the choice of pump class, and the selection of the type according to the load work. In practice, the pump is not operating at full capacity for most of the time.

It is a scientific method to control pump load directly by inverter.

Because the frequency converter can realize the soft stop and soft start of big motor, and avoid the voltage shock at startup, and it can reduce the failure rate of the motor, and prolong the use of orders. It also reduces the capacity requirement and reactive power loss of the power grid. Therefore, the promotion of the use of inverter for the purpose of energy conservation has become the focus of energy saving work departments and energy conservation work of various units.2. The selection of pump and the correct use of the pump also determine the real realization of the energy saving and consumption of the petrochemical industry

The manufacturing enterprises have the responsibility to communicate with customers, and provide reasonable product models and related services, and the user must have a good selection of this to prevent the phenomenon of unnecessary energy consumption of “big house drives small car”.

The pump is the heart of the refinery, and the total amount of logistics during the refining process is about 40 times that of crude oil processing, so it is conceivable that the power consumption is large. In the refining plant, the electric motor is one of the most widely used electrical equipment. And most of its load is machine pump, and the fixed speed pump is only 30% ~ 40% of the power consumed by process logistics. And 60% ~ 70% of the power consumption is due to the pressure drop of the throttle control and the pressure drop of the pump outlet valve caused by the capacity of the handling capacity and the design margin.

Therefore, as the manager and the user of the pump, the pump should be selected rationally, and the selection should be reasonable. The matching of each component (pump, motor, various accessories) is the best and most reasonable. It is the key to improve the operation efficiency of pump. Secondly, it is necessary to select the appropriate modulated mode. Here are two conditions: the pump needs to be adjusted in time for the process flow or the pump itself is set to adjust the process parameters.

In the regulation, we should try to choose the variable speed regulation, do not need throttling regulation. As for the way to speed regulation, we should also analyze specific problems. If process parameters are basically stable, pump selection is too large, we take down the valve at the scene to regulate traffic, which can cause the pump work flow is far less than the rated flow, working pressure is much higher than the rated pressure, then, we can adopt the way of comparatively economy of cutting impeller outer diameter to adjust.

- More

Six Reasons Affecting Performance of Self-suction pump

February 2,2021

You know that the self-suction pump has a self-suction function, however, we often encounter the fact that after we have installed the water pump, the height of self-suction can’t be reached, so what are the factors that affect the self-suction performance of the self-suction pump? Let’s give you a brief introduction:

Self-Priming Pump EZX The main reasons for self-suction of self-suction pump:

1. Determination of the reservoir volume and the height of the reservoir

Liquid storage volume means that the volume of the liquid portion of the pump can be stored after the pump is stopped, which is the volume of the pump body below the lowest point of the pump inlet. This volume is mainly a part of the separation chamber of the extruding chamber and the gas liquid. The volume of liquid storage should not be less than half of the design flow. For example, the design flow of the pump, the reservoir volume is not less than, the storage volume is too small [that is, too little liquid stored in the pump]. This makes the time of self-suction increases, and can’t even self-suction; In addition to having sufficient reservoir volume, there must be a certain reservoir height, which is the height of the pump suction minimum to the center of the impeller. Usually, it is approximately equal to the impeller radius.

- More