Technology

CHEMICAL PUMP APPLICATION CERAMIC ALKALI PUMPS TYPE EAH-800-22

Model: Cemet alkali pumps EAH-800-22

Performance range:

Flow (Q): 8600m3 / h

Head (H): 22m

User: China Datang Corporation

Unit: 600MW

Model: Cemet alkali pumps EAH-800-22

Performance range:

Flow (Q): 8600m3 / h

Head (H): 22m

User: China Datang Corporation

Unit: 600MW

Advanced Cermet alkali pumps is a large-flow, low-lift, cantilever single-stage centrifugal pump. Particularly suitable for conveying highly abrasive and corrosive media. Its core technology is based on the Ceramic metal(cemet)efficient hydraulic model, using CFD design means, using the solid-liquid two-phase flow hydraulic design method, unique “ceramic + metal” composite manufacturing process.

Ceramic metal(Cermet)

Ceramic materials are professional and reliable. According to the characteristics of the conveying slurry, a ceramic material with high strength, wear resistance and corrosion resistance was developed. The unique injection molding technology was used to ensure the reliability of the combination of ceramic materials and metal components. The abrasion resistance test of the comparative material of the Institute of Casting and Wear-resistant Materials of Jian University shows that the wear resistance of silicon carbide ceramic material is 3.5 times higher than that of high chromium alloy (Cr30).

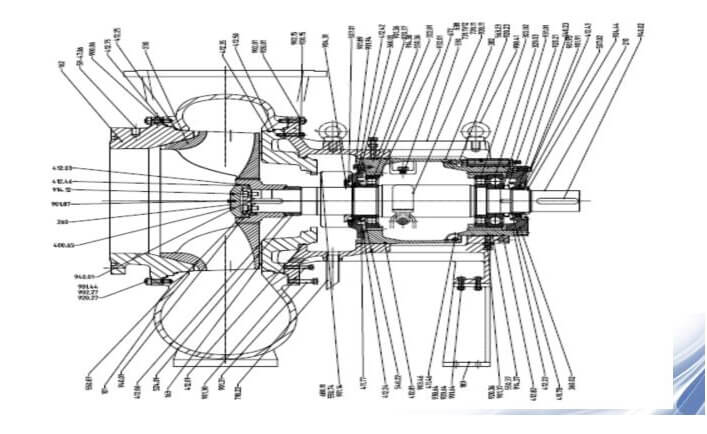

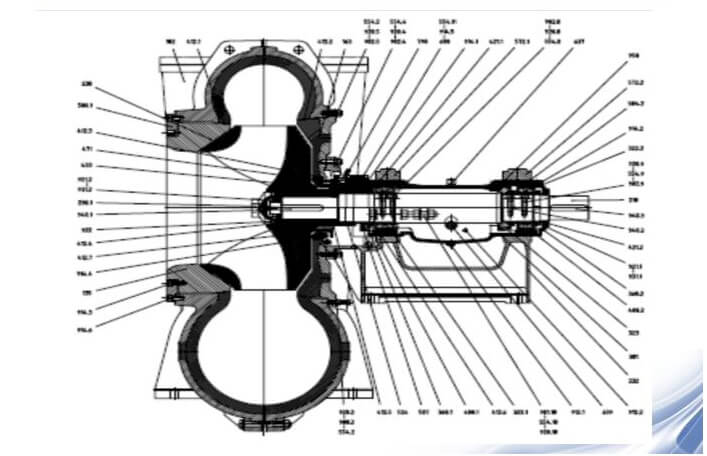

2.2 Ceramic metal pump lining

With optimized design and special manufacturing processing technology, silicon carbide ceramics are used for the pump housing and the pump cover lining. The external use of metal armor makes the pump highly reliable, safe, and easy to disassemble and install. The special ingredients and technology of ceramic materials ensure that the metal shell and the ceramic lining are integrated and tightly combined.

2.3 Ceramic metal impeller

The impeller is an in-line metal hub structure and the outer complex silicon carbide ceramic is manufactured as a whole. Fundamentally ensured the mechanical strength of the impeller and the wear and erosion of the crucible.

The impeller can be adjusted axially to maintain the impeller in a reasonable position in the pump chamber, thus ensuring that the pump operation is always in an efficient and stable state.

2.4 Shaft seal

The seal can move axially as a whole. The mechanical seal ring can move axially, and the mechanical seal static ring is fixed on the pump casing. It is better than the foreign product. The mechanical seal static ring is fixed on the front cover of the bearing chamber, which can avoid the radial runout of the mechanical seal after adjustment and lead to the mechanical seal. damage.

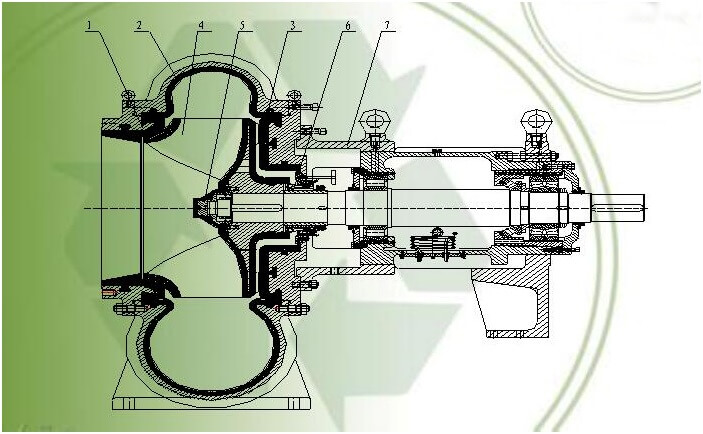

2.5 Pump Structure

The pump design uses a back-pull structure. When disassembling the impeller, mechanical seal and shaft assembly during maintenance, it is not necessary to disassemble the pipe line from pump. The bearings are lubricated with oil to ensure stable operation. The bearing part is composed of a bearing bracket and a bearing body. The bearing body can be moved axially on the bearing bracket to facilitate adjustment of the clearance and position of the impeller.

3.1 Comparison of Advanced Cermet alkali pumps and Domestic Desulfurization Pump:

| Factory project | Puyang Pump Factory | Shijiazhuang Pump Factory | SHENYANG NO.1 PUMP CO., LTD |

| Pump model | TL800-1000 | 800X-TL(R) | ACP-TIB30-32 |

| flow(m3/h) | 9460 | 9553 | 10500 |

| Head (m) m) | 30.3 | 32.2 | 31.5 |

| Effectiveness(%) | ≥86 | ≥86 | >88 |

| Rotating speed(r/min) | 495 | 495 | 495 |

| Features | Full metal type(Cr30A) | Housing rubber lining + metal impeller (A49) | Iron cass lining ceramic + ceramic impeller |

| Impeller life | 1-3 years | 1-3 years | >7年 |

1) Domestic initiative. Large-scale ceramic desulfurization pumps are a blank in China, and advanced ceramic metal desulfurization pumps are the first in China.

2) The performance is stable without attenuation. In the initial operation, the performance of the pump is comparable to that of other domestic manufacturers. However, the ceramic pump can be basically not worn during the entire life cycle, and it can ensure stable performance without attenuation.

Has outstanding advantages.

3) Abrasion resistance and corrosion resistance are good. Material wear and corrosion tests have shown that the comprehensive corrosion resistance of ceramic metal materials with silicon carbide as the main component is more than 3,5 times higher than that of high-grade alloys (Cr30).

4) Efficiency does not decay. During the entire life cycle, the efficiency of the advanced ceramic metal desulfurization pump does not decrease. The continuous running time is better than that of the metal pump. Especially, the metal pump will not be reduced in efficiency due to gap leakage during the later period of operation.

5) High security and reliability. The advanced ceramic metal desulfurization pump has better continuous operation reliability than the metal pump. The ceramic metal impeller can continue to operate for more than 7 years and the system can be safely operated for more than 20 years. Its service life is much higher than other types of desulfurization pumps.

6) Easy maintenance and low maintenance costs. When the ceramic metal parts of the advanced ceramic desulfurization pump are damaged by external damage, they can be repaired at the site or returned to the manufacturer according to the situation, and the whole part need not be scrapped, which greatly reduces the maintenance cost and time.

Conclusion: The unique wear resistance and corrosion resistance of EAH’s advanced ceramic metal desulfurization pump not only has a long life and a wide range of application that metal pumps cannot match, but also has extremely high efficiency in terms of energy saving, reduced maintenance, and reduced operating costs. obvious advantage.

- Long-term operating efficiency does not decay means saving current:

Take China Datang Corporation Xinyang Power Plant as an example:

The initial efficiency reaches the foreign product efficiency level, and the average efficiency after long-term operation is 2% higher than that of a German company’s product –

6%;

Annual energy saving calculation formula: 24 hours x310 days xU[cos4Φ (kWh)

In the formula; U is the voltage (V), [for the saving current (A), cosΦ is the electrical machinery power factor

The original pump is equipped with 710KW motor, U=6 (kV), rated current 89.1 (A), cosΦ>=0. SI is calculated by the average operating efficiency 4S higher than that of a German company, [= 3.24 (4),

Single pump power up to 20.29 million kWh. According to the Henan on-grid tariff of RMB 0.4244 /kWh, the savings in electricity charges RMB 8.61 million was calculated. Two power station units 2 towers, ceramic metal slurry circulation pump saves RMB 17.22 million per year, and it can save RMB86.11076 million in five years.

2, to protect more than five years without maintenance, no replacement parts, save maintenance costs:

Take a 710kW slurry circulating pump as an example:

Calculated according to the 2 tower’S pump, spare parts can be saved within five years (42-60) xS = 3364S0 million (domestic production of impellers need to riCI million, before and after the shields need about 3-5 million, according to five years replacement Calculations for three sets of impellers and three sets of front and rear guard plates required five years for a pump (14-20) X 3 = 42-60 million yuan for spare parts).

The above two items total savings of 680. 4-1513. 2 million.

3.23.2 Comparison of advanced ceramic desulphurization pumps and foreign desulfurization pumps:

| Factory project | Australia Waxman | Germany Duechting | SHENYANG NO.1 PUMP CO., LTD |

| Pump model | 800GSL | R0W800-950 ( I ) | ACP-TL800-32 |

| Heavy flow (m3/h) | 9492 | 10500 | 10500 |

| Head (m) | 31.2 | 31 | 31.5 |

| Effectiveness(%) | ≥86 | ≥86 | ≥86 |

| Speed (r/min) | 495 | 595 | 495 |

| Features | Tanned body rubber + metal impeller (A49) | Shell Village Ceramic + Ceramic Impeller | Shell lining ceramic + ceramic impeller |

| Impeller life | 3-5 years | >7 years | >7 years |

1) The performance of the pump is quite equivalent, and it can completely replace the imported helium from the power plant (600MW unit 丨 desulfurization pump actual operation record shows that taking the current and outlet pressure as an example, the advanced ceramic metal desulfurization spring completely exceeds the performance of the KSB desulfurization pump

2) Erosion and corrosion of niobium are superior to metallic ones. According to the survey of the power plant, the ceramic impeller has better wear and corrosion than the A49 and Noridur das. The service life of the sealing impeller is much less than that of the ceramic impeller. (Metal impeller 3 to 5 years, ceramic metal impeller 7 More than one year

3) Efficiency does not decay. During the entire life cycle, the hydraulic efficiency of the ceramic metal pump does not decrease. The continuous safe operation time is much higher than that of the metal pump, and in particular, the metal pump will not be reduced in efficiency due to the increase in clearance leakage at the later stage of operation.

4) Long continuous safe operation. The German Dnechting Ceramic Impeller is continuously operated for 3 to 5 years without damage. Even if it is not accidentally damaged, it can be repaired with a regeneration process. The service life is far higher than the metal pump. 1 The company’s advanced cermic metal were put into operation and operated stably and without any abrasion.

5) The abrasion resistance is better than the rubber lining type. After the rubber lining is worn out by the liquid, the damaged rubber particles can easily fall off, resulting in blockage of the nozzle of the absorption tower, reducing the desulfurization efficiency and affecting the reliability of the pump.

6) Easy maintenance and low maintenance costs. Easy maintenance, when the ceramic parts are damaged, they can be repaired on the spot or returned to the factory according to the situation, without the need to scrap the entire parts, greatly reducing maintenance costs and time.

Conclusion: energy-effective. Advanced ceramic metal desulfurization pumps are more cost-effective than imported pumps, and the price is 60-70 percent for similar import pumps. and the service is the best and the most convenient during the entire operation period.