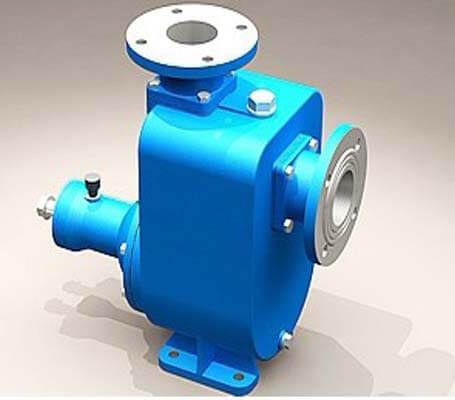

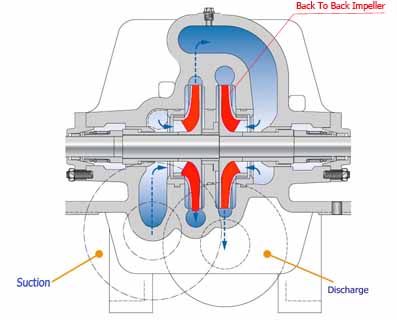

EZX Self-priming pump is the single stage, end suction self-priming pump with back-pull-out construction which is in compliance with ISO2858,ISO5199, EZX type self-priming pumps have good suction lift head, the maximum suction head can be up to 7m. The EZX type self-priming pumps are usually applied in transferring corrosive liquid, like vitriol, nitric acid, sea water, sulfur liquid, etc. .EZX chemical self-priming pump is your ideal option for chemical controlling and automatic process. Foot valves are not necessary in the pipe system and some liquid should be filled in the pump chamber before starting the pump.

Features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in EU-Flo Pump.

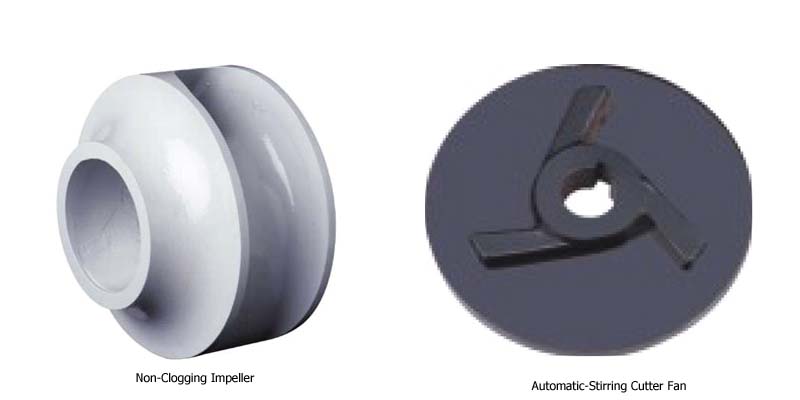

- Optimized impeller has high efficiency.

- Back-pull-out construction is easy to maintenance and replacing the spare parts.

- The shaft sealing is optional for single mechanical seal, double mechanical seal, cartridge mechanical seal and soft packing.

- Standard stuffing box cooling jacket integrated inside the casing cover allows the pump to transfer high temperature liquid.

- Standard finned bearing bracket or bracket with cooling jacket to ensure long bearing life and stable pump working.

- Standard bearing design is grove bearing, Grease lubrication

- Complete scopes are machined already for your complete monitor system to the pump.

- The suction and discharge nozzle meet ISO2858 standards or according user’s application.

- Heavy duty service design, the shaft can absord the huge and unstable torque.

Benefits

- Advance and modular design with fine production that is supplied by EU-Flo Pump.

- Good quality with competitive prices

- Comparently high efficiency as compared with similar products in the market.

- Many choices for material, cast steel, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Excellent pumps with fast delivery.

- Long lifetime and easy maintenance.

Application

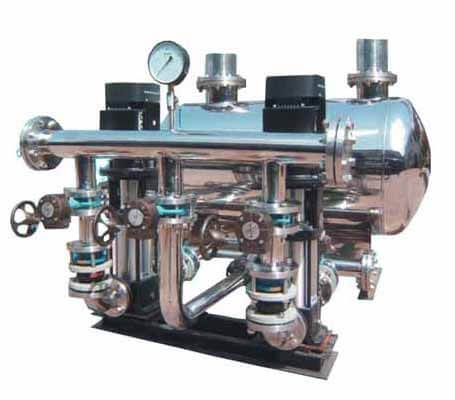

- Municipal water supply

- Flood pumping station

- Sewage Treatment Plant

- Water Circulation

- General Industries

- Power Plant

- Industrial water treatment

Sewage and Effluent treatment plants.

- Plumbing & sanitary

- Fire- fighting

- Metal Smelting

- Mineral

- Marine & offshore

Aboard ships as bilge, deck wash pump & engine cooling pump

- Oil& Gas

Loading , Unloading and transfer of tricky liquids viz. oils , solvents , gas oils , minerals , oils , grease, petrol, seawater etc

- • Low NPSH process circulation duty.

Operation Range

- Capacity

- up to 418L/s (1500m3h), or as per tailor-made.

- Head

- up to 160m(525ft), or as per taitor- made.

- Working temperature

- up to 120°C

- Design pressure

- 6Mpa/2.5Mpa

- Nozzle

- up to 500mm or tailor design. Flange standard can be DIN,AS, ANSI,JIS,GOST or other standard.